Pressure Seal Globe Valves

The Gold Standard in The Industry

YVI’s Cast Steel Pressure Seal Globe Valves, with their body-guided discs and seal-welded seat rings, are meticulously designed for optimal flow precision and seal integrity. Reinforced with gland eye bolt pins welded on both ends and equipped with API 622 certified graphite stem packing, they offer exceptional performance and reliability under high-pressure conditions, making them a steadfast solution in any rigorous industrial setting.

Pressure Seal GLOBE Valve

YVI Cast Steel Pressure Seal Valves are designed, manufactured, and tested in accordance with ASME B16.34, API 623, MSS SP-144, and API 598. YVI offers size ranges from 2” through 24” diameters in pressure classes 600# through 2500# with end connections in either RFFE, RTJ, and Buttweld. Common materials of construction such as WCB, LCB, LCC, WC6, WC9, C5, C12, and Austenitic Stainless Steel Grades are all available along with other materials upon request. To assure casting quality, all pressure-containing castings are produced in-house. YVI also offers our Pressure Seal Bonnet Globe Valves in a Y-pattern design for throttling applications requiring a have Cv value than the traditional globe valve design.

Parts & Available Materials

| No. | Part | Carbon Steel | Stainless Steel | Low Temperature | High Temperature | NACE Service |

| 1 | Body | ASTM A216 WCB | ASTM A351 CF8M | ASTM A352 LCC | ASTM A217 WC9 | ASTM A216 WCB |

| 2 | Disc | ASTM A105N+STL.6 | ASTM A182 F316+STL.6 | ASTM A350-LF2+STL.6 | ASTM A182 F22+STL.6 | ASTM A105N+STL.6 |

| 3 | Stem | ASTM A182 F6a | ASTM A182 F316 | ASTM A182 F304 | ASTM A182 F6a | ASTM A182 F6a(NACE) |

| 4 | Stuffing Box | ASTM A182 F6a | ASTM A182 F316 | ASTM A182 F304 | ASTM A182 F6a | ASTM A182 F6a(NACE) |

| 5 | Sealing Ring | SS304 + Graphite<br>SS316L | SS304 + Graphite<br>SS316L | SS304 + Graphite<br>SS316L | SS304 + Graphite<br>SS316L | SS304 + Graphite<br>SS316L |

| 6 | Yoke | ASTM A216 WCB | ASTM A351 CF8M | ASTM A352 LCC | ASTM A217 WC9 | ASTM A216 WCB |

| 7 | Spacer Ring | ASTM A182 F6a | ASTM A182 F316 | ASTM A182 F304 | ASTM A182 F6a | ASTM A182 F6a(NACE) |

| 8 | Packing | Graphite | Graphite | Graphite | Graphite | Graphite |

| 9 | Gland | ASTM A276 410 | ASTM A276 316 | ASTM A276 304 | ASTM A276 410 | ASTM A276 410 |

| 10 | Gland Flang | ASTM A216 WCB | ASTM A351 CF8M | ASTM A352 LCC | ASTM A217 WC9 | ASTM A216 WCB |

| 11 | Eye Bolt | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7 | ASTM A193 B16 | ASTM A193 B7M |

| 12 | Nut | ASTM A193 2H | ASTM A193 8 | ASTM A193 7 | ASTM A193 7 | ASTM A193 2HM |

| 13 | Stem Nut | ASTM A439 GR D-2 | ASTM A439 GR D-2 | ASTM A439 GR D-2 | ASTM A439 GR D-2 | ASTM A439 GR D-2 |

| 14 | Handwheel Cover | ASTM A29 Type 1025 | ASTM A29 Type 1025 | ASTM A29 Type 1025 | ASTM A29 Type 1025 | ASTM A29 Type 1025 |

| 15 | Inpactor Handwheel | Ductile iron | Ductile iron+Zn | Ductile iron | Ductile iron | Ductile iron |

| 16 | Impact Block | ASTM A29 Type 1045 | ASTM A29 Type 1045 | ASTM A29 Type 1045 | ASTM A29 Type 1045 | ASTM A29 Type 1045 |

| 17 | Disc Nut | ASTM A276 410 | ASTM A276 316 | ASTM A276 304 | ASTM A276 410 | ASTM A276 410(NACE) |

Material list, other materials available/provided.

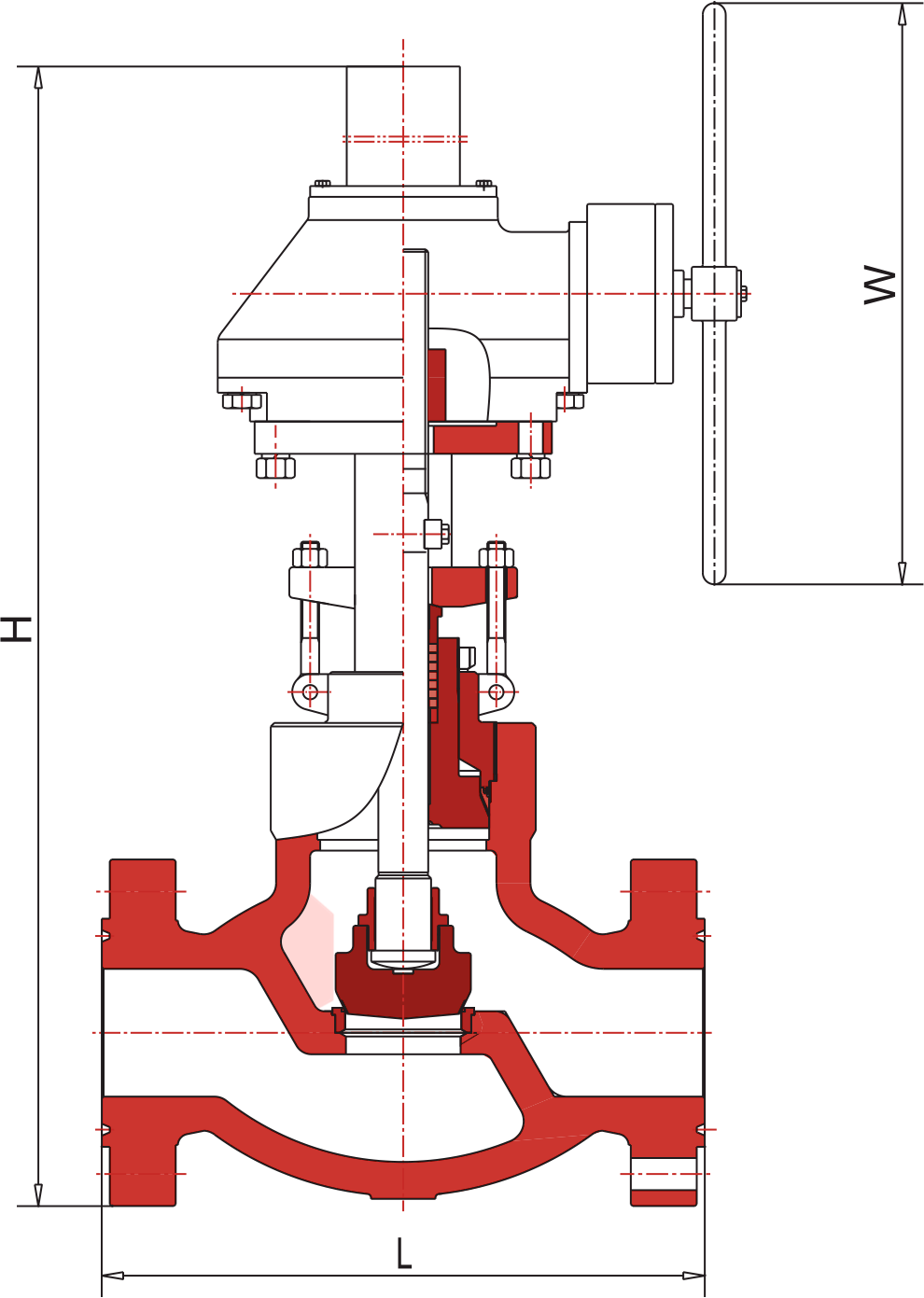

Dimension Data

Class 600

| NPS | in | 2” | 2 1/2” | 3” | 4” | 5” | 6” | 8” | 10” | 12” | 14” | 16” |

| L(BW) | in | 7 | 8.5 | 10 | 12 | 15 | 18 | 23 | 28 | 32 | – | – |

| mm | 178 | 216 | 254 | 305 | 381 | 457 | 584 | 711 | 813 | – | – | |

| L1(RF) | in | 11.5 | 13 | 14 | 17 | 20 | 22 | 26 | 31 | 33 | 35 | 39 |

| mm | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | 991 | |

| L2(RTJ) | in | 11.6 | 13.1 | 14.1 | 17.1 | 20.1 | 22.1 | 26.1 | 31.1 | 33.1 | 35.1 | 39.1 |

| mm | 295 | 333 | 359 | 435 | 511 | 562 | 663 | 790 | 841 | 892 | 994 | |

| W | in | 9.8 | 11.8 | 13.8 | 17.7 | 19.7 | 21.3 | 21.3 | 24 | 24 | 32 | 32 |

| mm | 248.9 | 299.7 | 350.5 | 449.6 | 500 | 540 | 540 | 610 | 610 | 810 | 810 | |

| H | in | 21.7 | 24.8 | 26.8 | 29.5 | 39.4 | 45.3 | 49.2 | 55.1 | 61 | 70.9 | 85 |

| mm | 551.2 | 629.9 | 680.7 | 749.3 | 1000 | 1150.6 | 1249.7 | 1399.5 | 1549.4 | 1800 | 2150 | |

| WT(RF) | kg | 45 | 55 | 85 | 135 | 190 | 305 | 620 | 1310 | 1900 | 2720 | 3150 |

| WT(BW) | kg | 35 | 45 | 60 | 95 | 150 | 230 | 540 | 1150 | 1720 | 2530 | 2900 |

Class 900

| NPS | in | 2” | 2 1/2” | 3” | 4” | 6” | 8” | 10” | 12” | 14” | 16” |

| L(BW) | in | 8.5 | 10 | 12 | 14 | 20 | 26 | 31 | 36 | 39 | 43 |

| mm | 216 | 254 | 305 | 356 | 508 | 660 | 787 | 914 | 991 | 1092 | |

| L1(RF) | in | 14.5 | 16.5 | 15 | 18 | 24 | 29 | 33 | 38 | 40.5 | 44.5 |

| mm | 368 | 419 | 381 | 457 | 610 | 737 | 838 | 965 | 1029 | 1130 | |

| L2(RTJ) | in | 14.6 | 16.6 | 15.1 | 18.1 | 24.1 | 29.1 | 33.1 | 38.1 | 40.9 | 44.9 |

| mm | 371 | 422 | 384 | 460 | 613 | 740 | 841 | 968 | 1038 | 1140 | |

| W | in | 14 | 14 | 22 | 20* | 24* | 24* | 24* | 32* | 32* | 39.4* |

| mm | 355.6 | 355.6 | 560 | 540* | 610* | 610* | 610* | 810* | 810* | 1000* | |

| H | in | 24.4 | 25.2 | 22 | 33.5 | 39.1 | 53.1 | 61 | 68.9 | 78.8 | 91 |

| mm | 619.8 | 640.1 | 561 | 850.9 | 994 | 1348.7 | 1549.4 | 1749.6 | 2000.3 | 23114 | |

| WT(RF) | kg | 84 | 110 | 116 | 179 | 441 | 1050 | 1720 | 2300 | 3350 | 4000 |

| WT(BW) | kg | 58 | 74 | 84 | 137 | 378 | 945 | 1520 | 2050 | 3050 | 3600 |

Class 1500

| NPS | in | 2” | 2 1/2” | 3” | 4” | 6” | 8” | 10” | 12” | 14” |

| L(BW) | in | 8.5 | 10 | 12 | 16 | 22 | 28 | 34 | 39 | 42 |

| mm | 216 | 254 | 305 | 406 | 559 | 711 | 864 | 991 | 1067 | |

| L1(RF) | in | 14.5 | 155 | 18.5 | 215 | 27.8 | 328 | 39 | 44.5 | 495 |

| mm | 368 | 419 | 470 | 546 | 705 | 832 | 991 | 1130 | 1257 | |

| L2(RTJ) | in | 14.6 | 16.6 | 18.6 | 21.6 | 28.1 | 33.2 | 39.4 | 45.1 | 50.3 |

| mm | 371 | 422 | 473 | 549 | 711 | 841 | 1000 | 1146 | 1276 | |

| W | in | 13.8 | 17.7 | 17.7 | 18.1 | 24 | 31.9 | 39.4 | 39.4 | 39.4 |

| mm | 350 | 450 | 450 | 460* | 610* | 810* | 1000* | 1000* | 1000* | |

| H | in | 19.4 | 23.8 | 23.8 | 32.2 | 48.4 | 50.1 | 57.8 | 91 | 106 |

| mm | 492 | 605 | 605 | 819 | 1229 | 1272 | 1468 | 23114 | 26924 | |

| WT(RF) | kg | 84 | 116 | 143 | 236 | 918 | 1764 | 2680 | 3400 | 4300 |

| WT(BW) | kg | 58 | 62 | 128 | 168 | 781 | 1502 | 2280 | 2830 | 3600 |

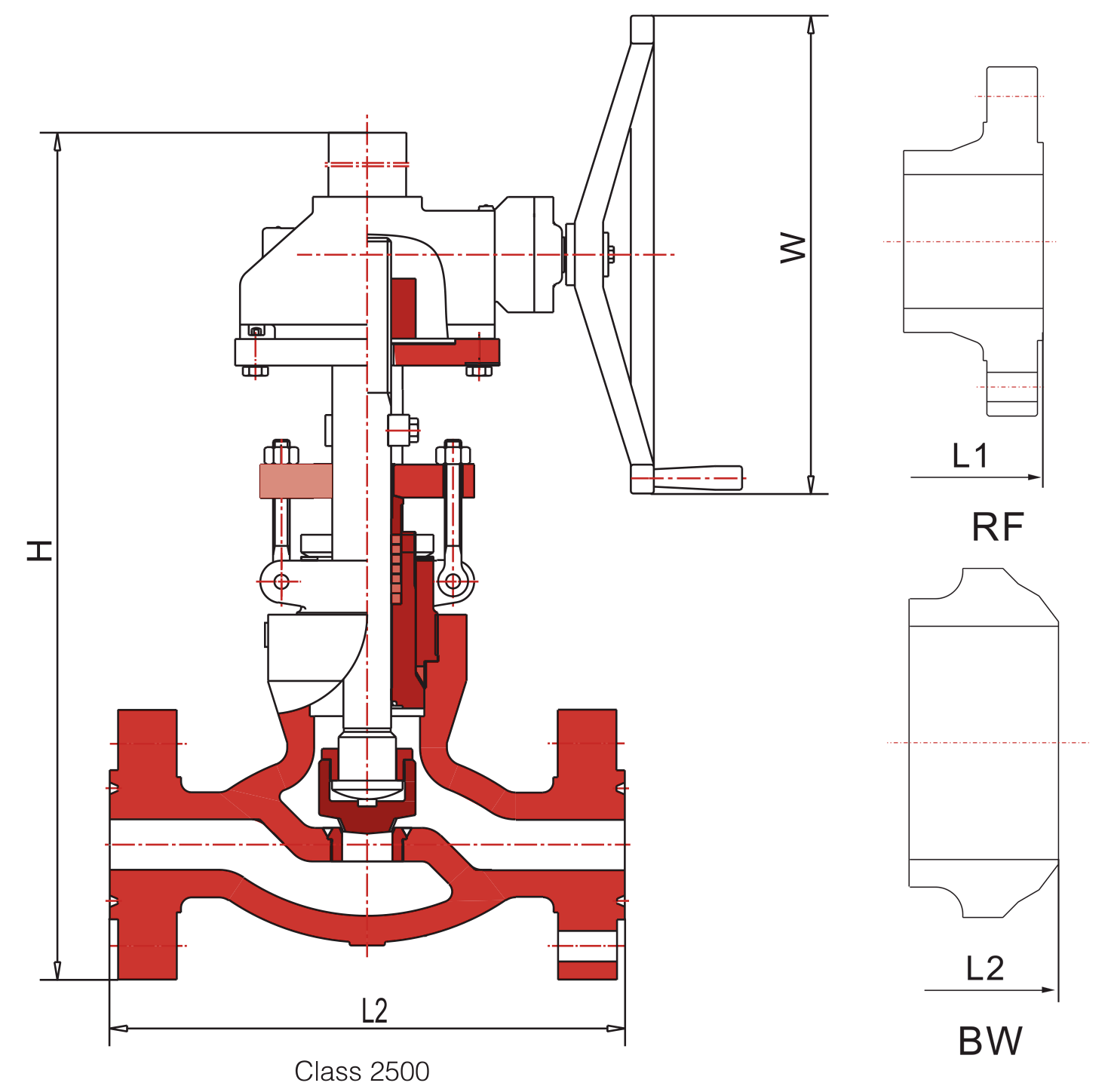

Class 2500

| NPS | in | 2” | 2 1/2” | 3” | 4” | 6” | 8” | 10” | 12” |

| L(BW) | in | 11 | 13 | 14.5 | 18 | 24 | 30 | 36 | 41 |

| mm | 279 | 330 | 368 | 457 | 610 | 762 | 914 | 1041 | |

| L1(RF) | in | 17.8 | 20 | 22.8 | 26.5 | 36 | 40.3 | 50 | 56 |

| mm | 451 | 508 | 578 | 673 | 914 | 1022 | 1270 | 1422 | |

| L2(RTJ) | in | 17.9 | 20.3 | 23 | 26.9 | 36.5 | 40.9 | 50.9 | 56.9 |

| mm | 454 | 514 | 584 | 683 | 927 | 1038 | 1292 | 1445 | |

| W | in | 16 | 20 | 19.7 | 24 | 24 | 39.4 | 39.38 | 39.38 |

| mm | 400 | 500 | 500 | 610* | 610* | 1000* | 1000* | 1000* | |

| H | in | 24.3 | 30.7 | 27.8 | 512 | 53.9 | 62.3 | 100 | 106 |

| mm | 617.2 | 779.8 | 705 | 1300.5 | 1369.1 | 1583 | 2540 | 2692.4 | |

| WT(RF) | kg | 105 | 163 | 221 | 525 | 1313 | 2520 | 3300 | 4200 |

| WT(BW) | kg | 74 | 116 | 147 | 368 | 973 | 2100 | 2500 | 3300 |

All technical data is subject to change without notice.