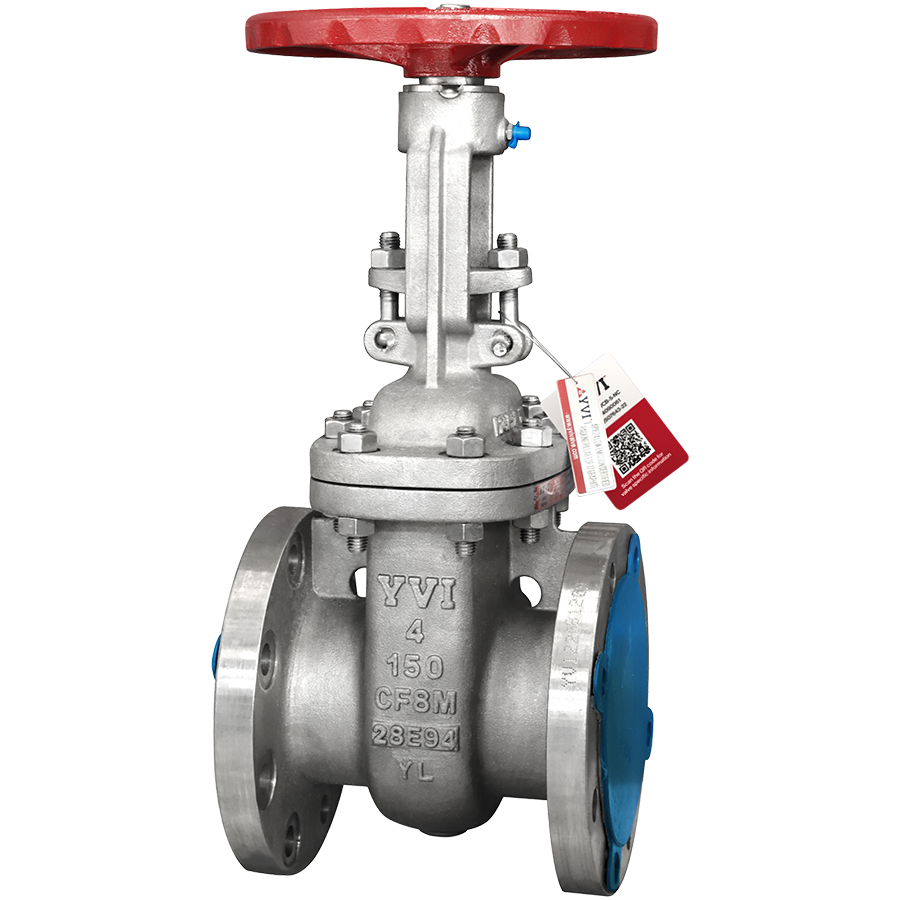

Corrosion Resistant Alloy Gate Valves

(API 603)

YVI Corrosion Resistant Gate Valves are designed, manufactured, and tested in accordance with ASME B16.34, API 603,and API 598. Low Emissions Qualification to API 624, ISO 15848-1, and TA Luft is standard. YVI offers sizes ranging from 2” through 12” diameters in pressure classes 150# and 300#. Fort other sizes and pressure classes, please see our API 600 Gate valve offering. YVI also has the capabilities to automate valves in-house using pneumatic, hydraulic, or electric actuation. Common Austenitic Stainless Steel Grades such as CF8M, CG8M, and CF8C are all available along with other materials upon request. To ensure casting quality, all pressure-containing castings are produced in-house.

Corrosion Resistant Alloy Gate Valves

Design Features

- API 624 / ISO 15848-1 Low Fugitive Emission Compliant

- Flexible Wedge (Standard on all Sizes and Pressure Classes)

- Integral Seat

- Gland Eye Bolt Pins are Welded on Both Ends

Optional Features

- Optional Stem Extension

- Optional Double Packing with Lantern Ring

- Optional Live Loaded Gland Flange

- Optional Bellow Seal

Corrosion Resistant Alloy Gate Valves

YVI Cast Steel Gate Valves are designed, manufactured, and tested in accordance with ASME B16.34, API 600, API 594, API 623, and API 598. Items have been examined in accordance with API RP-591 and are Low Emissions Certified to API 624, ISO 15848-1, and TA Luft. YVI offers sizes ranging from 2” through 60” diameters in pressure classes 150# through 2500# with end configurations in either RFFE, RTJ, and Buttweld. YVI also has the capabilities to automate valves in-house using pneumatic, hydraulic, or electric actuation. Common materials of construction such as WCB, LCB, LCC, WC6, WC9, and C5 are all available along with other materials upon request. To ensure casting quality, all pressure-containing castings are produced in-house.

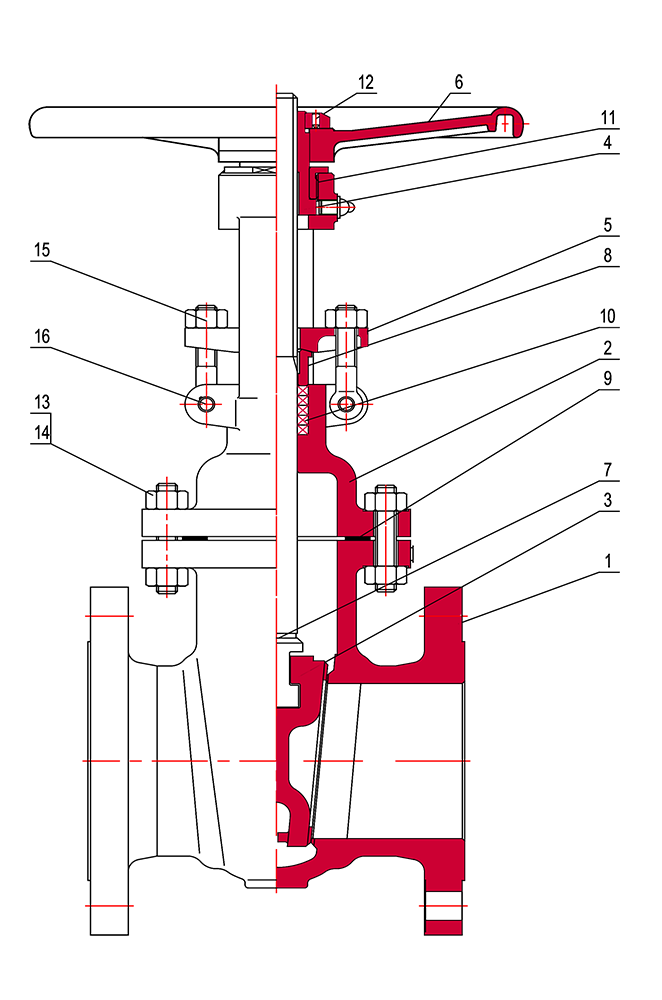

Parts & Available Materials

| No. | Part | Stainless Steel (API Trim 10) | Stainless Steel (API Trim 12) | Stainless Steel (API Trim 16) |

| 1 | Body | ASTM A351 CF8M | ASTM A351 CF8M + HF | ASTM A351 CF8M + HF |

| 2 | Bonnet | ASTM A351 CF8M | ASTM A351 CF8M | ASTM A351 CF8M |

| 3 | Wedge | ASTM A351 CF8M | ASTM A351 CF8M | ASTM A351 CF8M + HF |

| 4 | Stem Nut | ASTM A439 D-2 | ASTM A439 D-2 | ASTM A439 D-2 |

| 5 | Gland Flange | ASTM A351 CF8M | ASTM A351 CF8M | ASTM A351 CF8M |

| 6 | Handwheel | DUCTILE IRON | DUCTILE IRON | DUCTILE IRON |

| 7 | Stem | ASTM A182 F316 | ASTM A182 F316 | ASTM A182 F316 |

| 8 | Gland | ASTM A276 316 | ASTM A276 316 | ASTM A276 316 |

| 9 | Gasket | 316SS + GRAPHITE | 316SS + GRAPHITE | 316SS + GRAPHITE |

| 10 | Packing | GRAPHITE | GRAPHITE | GRAPHITE |

| 11 | Retaining Nut | STAINLESS STEEL | STAINLESS STEEL | STAINLESS STEEL |

| 12 | Handwheel Nut | STAINLESS STEEL | STAINLESS STEEL | STAINLESS STEEL |

| 13 | Bonnet Stud | ASTM A193 B8 | ASTM A193 B8 | ASTM A193 B8 |

| 14 | Bonnet Nut | ASTM A194 8 | ASTM A194 8 | ASTM A194 8 |

| 15 | Eye Bolt | ASTM A193 B8 | ASTM A193 B8 | ASTM A193 B8 |

| 16 | Eye Bolt Pin | Stainless Steel | Stainless Steel | Stainless Steel |

Material list, other materials available/provided.

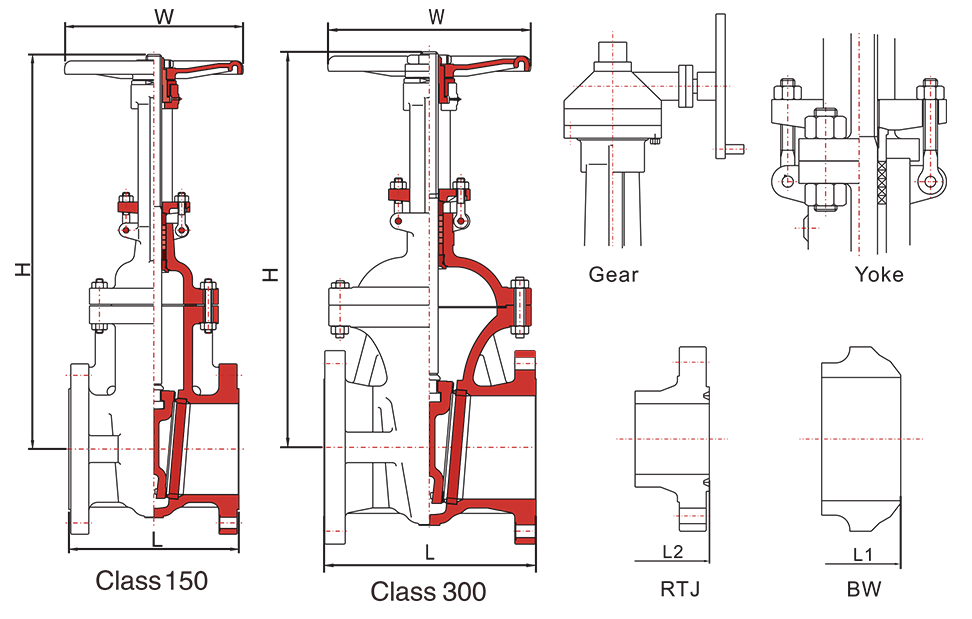

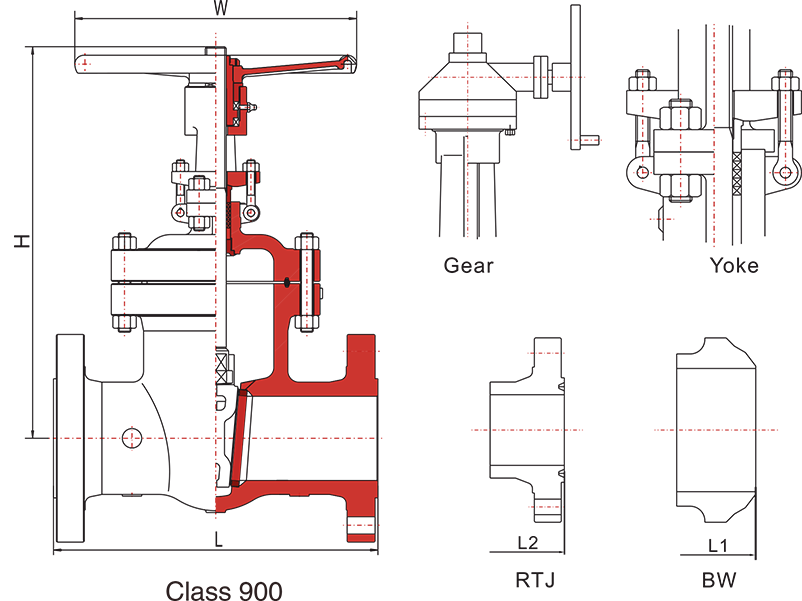

Dimension Data

Class 150

| NPS | in | 2″ | 3″ | 4″ | 6″ | 8″ | 10″ | 12″ |

| DN | mm | 50 | 80 | 100 | 150 | 200 | 250 | 300 |

| L (RF) | in | 7 | 8 | 9 | 10.5 | 11.5 | 13 | 14 |

| mm | 178 | 203 | 229 | 267 | 292 | 330 | 356 | |

| W | in | 5.9 | 7.9 | 9.8 | 11.8 | 11.8 | 13.8 | 15.7 |

| mm | 150 | 200 | 250 | 300 | 300 | 350 | 400 | |

| H | in | 11.1 | 13.8 | 16.9 | 22.9 | 28.1 | 33.9 | 40.2 |

| mm | 283 | 350 | 429 | 582 | 714 | 862 | 1021 | |

| WT (RF) | kg | 16 | 30 | 47 | 81 | 123 | 190 | 271 |

Class 300

| NPS | in | 2 | 3 | 4 | 6 | 8 | 10 | 12 |

| DN | mm | 50 | 80 | 100 | 150 | 200 | 250 | 300 |

| L (RF) | in | 8.5 | 11.1 | 12 | 15.9 | 16.5 | 18 | 19.8 |

| mm | 216 | 282 | 305 | 403 | 419 | 457 | 502 | |

| W | in | 7.9 | 9.8 | 11.8 | 13.8 | 15.7 | 17.7 | 19.7 |

| mm | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| H | in | 11.8 | 14.4 | 17.3 | 23.6 | 29.1 | 36.3 | 41.9 |

| mm | 300 | 366 | 440 | 599 | 738 | 921 | 1065 | |

| WT (RF) | kg | 24 | 49 | 71 | 143 | 232 | 283 | 400 |

All technical data is subject to change without notice.